Product Catalog

Deep Groove Ball Bearing

Self Aligning Ball Bearing

Cylindrical Roller Bearing

Spherical Roller Bearing

Angular Contact Ball Bearing

Tapered Roller Bearing

Thrust Ball Bearing

Thrust sphercial roller bearing

Bearing Unit

Linear Bearing

Spherical plain bearing

Stainless Steel Bearing

Taper Bush

Axial Needle Roller and Cage Assemblies

Drawn Cup Needle Roller Bearing Clutch

Machined needle roller bearing

Drawn cup needle roller bearing

Needle Roller and Cage Assemblies

Slide Guide Rails

Ball Screw Support Bearing

Ball Screw Support Bearings

Optical Axis

d 130-170mm

Introduction

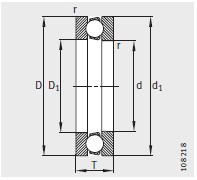

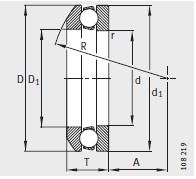

&Nbsp; & nbsp; features thrust ball bearing is composed of shaft ring, seat ring, ball and cage components. These bearings are separable; i.e. ball and cage assemblies and washers can be installed separately. in addition to the series with flat seat ring, it also includes the series with compensating static angle misalignment. The aligning seat ring is usually used in combination with the aligning seat washer. thrust ball bearing has two designs: one-way bearing and two-way bearing. Both of them can bear high axial force but not radial force. one way thrust ball bearing can bear axial force in one direction. 511 , 512 , 513 and 514 have a flat race. They shall not be installed in the wrong center or the shaft and bearing seat shall be inclined relatively. The bearings of angle adjusting device 532 and 533 series have self-aligning race. The thrust ball bearing can compensate the static misalignment of the shaft and the bearing seat by improving the design of the seat ring and using it in combination with the washers of the aligning seat U2 and U3 . two way thrust ball bearing can bear axial force in two directions. Adjustment. The bearings of angle adjusting device 542 and 543 series have self-aligning race. The thrust ball bearing can compensate the static misalignment of the shaft and the bearing seat by improving the design of the seat ring and using it in combination with the washers of the aligning seat U2 and U3 . The working temperature range of thrust ball bearing is & ndash; 30 ℃ to + 150 ℃ and restricted by lubricant. bearings with pressed steel plate cages have no cage suffix. the suffix of solid brass window cage is MP , see the table. please refer to the table for cage design forms related to ID code.

| series | stamping steel plate holder | solid brass cage |

| ID code | ||

| 511 | to 28 | '

return html

};

function Navigator() {

var type = "pc";

if (navigator.userAgent.indexOf('iPad') != -1 || navigator.userAgent.indexOf('iPhone') != -1 || navigator.userAgent.indexOf('Android') != -1) {

type = "ipad"

}

return type

};

|