Product Catalog

Deep Groove Ball Bearing

Self Aligning Ball Bearing

Cylindrical Roller Bearing

Spherical Roller Bearing

Angular Contact Ball Bearing

Tapered Roller Bearing

Thrust Ball Bearing

Thrust sphercial roller bearing

Bearing Unit

Linear Bearing

Spherical plain bearing

Stainless Steel Bearing

Taper Bush

Axial Needle Roller and Cage Assemblies

Drawn Cup Needle Roller Bearing Clutch

Machined needle roller bearing

Drawn cup needle roller bearing

Needle Roller and Cage Assemblies

Slide Guide Rails

Ball Screw Support Bearing

Ball Screw Support Bearings

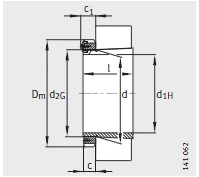

Optical Axis

d 560-710mm

Introduction

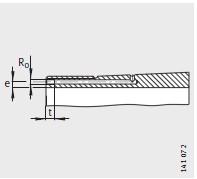

tightening sleeve for optical axis and step axis Black; Font size: 14px '> cone hole shaft bearing installation in circle column axis . There is no need to use other methods to fix it except for amount and the axis axis bearing shall be installed at any position of optical axis . if you are in the level ladder axis for use on belt positioning ring of tight in this way, also makes axis for disassembly, it is easier to Jane . Font size: 14px '> on interface tight set, lock nut and stop moving pad ring. 'font-family: Microsoft YaHei; Font size: 14px '> moving card replacing stop moving pad circle. Black; Sup > 2 . Font-family: Microsoft YaHei; font size: Font-family: Microsoft YaHei; Font size: 14px '> H240 and h241 series 30 . Black; Font size: 14px '> set size is used for metric system axis . 'font family: Microsoft YaHei; font size: 14px '> protocol for goods . adopt hydraulic method large axis it needs a lot of force for installation and disassembly. The method of liquid pressure can make installation and disassembly change more easily. Some tight fixed set cone there is oil groove on the surface, and the screw is grain is the end is pump is followed by header . Family: Microsoft YaHei; Font size: 14px '> with after affix Hg . pump connect < span style=